Increase Performance: Exactly How Upgrading Undercarriage Parts Can Enhance Performance

Increase Performance: Exactly How Upgrading Undercarriage Parts Can Enhance Performance

Blog Article

Key Parts: Undercarriage Components for Heavy Machinery

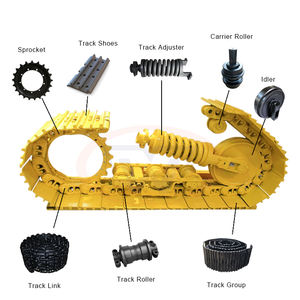

In the realm of hefty machinery, the undercarriage serves as a vital foundation that ensures the smooth procedure and long life of the devices. Trick elements such as track footwear, rollers, idlers, sprockets, and track chains play a pivotal duty in the performance and performance of these huge makers.

Track Shoes

Track footwear play a vital role in the performance and durability of hefty equipment's undercarriage system. Track shoes come in various layouts and materials to suit various operating problems and terrains.

The design of track footwear is engineered to give ideal ground contact, reducing slippage and enhancing the machine's ability to navigate tough surfaces. Proper maintenance and normal evaluation of track footwear are necessary to protect against early wear and guarantee the undercarriage system's durability. Any type of signs of wear, such as uneven wear patterns or extreme damages, need to be resolved quickly to avoid expensive repair work and downtime.

Rollers

Rollers are essential parts of the undercarriage system in heavy machinery, working in conjunction with track shoes to sustain and assist the equipment's motion. These round steel parts are purposefully positioned along the undercarriage frame and can be found in different types such as provider rollers, track rollers, and idlers. Service provider rollers help in supporting the weight of the equipment, while track rollers assist distribute the load and make certain smooth track shoe articulation (undercarriage parts). Idlers work as a tensioning device for the track chain, maintaining correct track stress for optimum performance.

To improve sturdiness and efficiency, rollers are usually created from premium materials like built steel, offering resistance to deterioration under heavy loads and severe working problems. Proper lubrication is crucial to lower rubbing between the rollers and track footwear, expanding the life expectancy of both elements. Regular assessment and maintenance of rollers are vital to protect against premature wear and possible break downs, making sure the constant procedure of heavy machinery.

Idlers

Idlers play an essential function in the undercarriage system of hefty machinery, offering as vital components for maintaining appropriate track chain stress and guaranteeing ideal device efficiency. Idlers are in charge of leading the track chain and sustaining the weight of the devices. These cylindrical rollers are strategically placed along the track structure to distribute the maker's weight equally, lower vibration, and improve stability throughout operation.

Appropriately operating idlers help stop early wear on the track chain and various other undercarriage components, ultimately expanding the lifespan of the machinery. They additionally add to fuel performance by minimizing moving resistance and lessening the power needed to move the tools (undercarriage parts). Routine inspection and upkeep of idlers are crucial to spot any type of indications of wear, imbalance, or damage that could lead to performance concerns or downtime

Gears

Playing a critical duty investigate this site in the you could check here undercarriage system of hefty machinery, gears are necessary parts accountable for transferring power from the device to the track chain. Sprockets include toothed wheels or equipments that harmonize with the web links of the track chain, enabling the equipment to move ahead or backward. By recognizing the importance of gears in the undercarriage system, operators and maintenance employees can successfully manage these elements to improve the overall efficiency and integrity of heavy equipment.

Track Chains

An important component of the undercarriage system in hefty machinery, track chains play a vital role in leading the movement and sustaining of the tools. Track chains are robust metal chains that connect the drive gear to the wheels or tracks of the heavy equipment. These chains are developed to endure tremendous tension, wear, and anxiety while guaranteeing smooth and efficient operation of the machinery.

Track chains are comprised of private links that are attached by pins and bushings. The layout of track chains is vital as it directly influences the total efficiency and longevity of the heavy equipment. Proper upkeep of track chains is vital to prevent early wear, lower downtime, and extend the life-span of the tools.

Regular inspections, lubrication, and changes are essential to keep track chains in optimum condition. Failing to keep track chains can cause increased functional expenses because of frequent replacements and repair work. Spending in premium track chains and sticking my explanation to a rigorous maintenance timetable is crucial to maximizing the efficiency and longevity of hefty equipment.

Verdict

Finally, the key components for hefty machinery undercarriage components include track footwear, rollers, idlers, gears, and track chains. These parts are important for the correct performance and procedure of hefty equipment, offering stability, support, and traction. It is vital for operators and upkeep workers to routinely check and preserve these elements to make sure the safety and performance of the machinery.

Trick parts such as track shoes, rollers, idlers, gears, and track chains play an essential role in the performance and efficiency of these enormous equipments (undercarriage parts). Carrier rollers help in sustaining the weight of the equipment, while track rollers aid distribute the tons and make certain smooth track shoe expression. Idlers act as a tensioning device for the track chain, maintaining proper track tension for ideal efficiency

Track chains are durable steel chains that connect the drive sprocket to the wheels or tracks of the heavy equipment.In conclusion, the key components for heavy machinery undercarriage parts include track footwear, rollers, idlers, gears, and track chains.

Report this page